Latest Posts

Week 10 update

It feels like we’re actually closing in on getting a kitchen back.

The countertops were templated, and we went to approve the slabs, as I posted about. We are indeed getting everything we want with the counters: no seams at all, stone windowsills, and a tall backsplash up to the sills. I think it’s going to look fabulous. The lead time is about 2 weeks, and I suspect that their arrival will mark the completion of the kitchen portion of the project.

The electricians also made good progress this week. The three nickel & glass pendants, all the undercabinet lights, and the recessed fixtures are in, complete with dimmers; and the majority of the outlets are operational. Still to be done are the Tiffany lamp, fixtures for the coat closet & pantry, outlet for the stove, and (most importantly) the subpanel for the extra circuits.

The range hood is installed and wired, but needs its vent duct

installed still (it’s a chimney style, so the ducting is entirely above

it).

The cabinets are now all installed. The installers were kind enough to modify the face frame of the microwave cabinet, since just about every countertop microwave on the market is a fraction of an inch wider than the 21″ opening on this cabinet. You would think the cabinet people and the microwave people would be on the same page here. This also gave us an opportunity to try out the cabinets’ stain, which we’ll be using on the cherry door to the pantry so it matches.

The light rail is up, as is all the starter moulding that backs up the crown. So the only things left from a cabinet perspective are installing the crown, installing a filler above the fridge, adjusting the doors to line up properly, and putting on the knobs & pulls.

Finish carpentry also needs to be completed before we can declare victory. Baseboards and window & door trim will go a long way to making the room feel like a room instead of a construction zone. The “belly moulding” and corner block window & door casings were delivered this week.

On the sunroom side of the project, we have a floor! We were told to feel free to use it as a deck this weekend, and I intend to go sit out there with a magazine and a beer just as soon as I finish posting this update. We’re told that framing for the walls and roof should happen this coming week, which I’ll be sure to post about.

One setback this week on the sunroom: the revelation that we’re going to need a railing to keep people from falling out of the sliding doors that we’re using as windows. I need to discuss further with the contractor in the morning, but my feeling is we will want some sort of metal railing that looks like a balcony railing. I spent several hours today researching what’s possible relatively inexpensively with off-the-shelf parts, and the following drawing is what I came up with. I think this will look fine, maybe even appropriate to the house if we dress it up like this.

Floor first

Progress

A lot of update today, aside from the countertop slabs.

The electrician was on site today, and installed our permanent in-ceiling cans (Cree CR6). These look great! He also installed one example of the pendants and one of the undercabinet lights.

Besides the lights, the electricians got about half the outlets & switches activated today. They anticipate being back on Friday to finish up the rest.

Also… the sunroom begins! We have a ledger (up against the house) and the start of the main outside beams. The weather appears to be improving this week more quickly than anticipated, so I am hoping for speedy progress on the rest of the sunroom framing this week.

Slabs

We went to approve the countertop slabs today.

There have been some other good developments today, which I’ll post about once the contractors leave for the day and I can get some pictures.

Week 9 report

Cabinet week! Fourteen of 22 cabinets went in this week, including all the lowers. Here’s the stack containing our mail sorter. These cabinets are just 12″ deep, with a skin beside them, to conceal the main plumbing chase. The top here will get crown moulding to fill in that hole.

The sink run of cabinets was a challenge because the floor is so far out of level — there’s a hump in the middle. The floor at the right hand end (under the mail sorter) is a full 1 1/2 inches lower than the high point, just to the left of the sink. Because of this, we don’t actually have the full 93 inches of height the design calls for with everything level and in line. This is where it pays to have a couple of actual cabinetmakers installing your cabinets. Fortunately, because the mail-sorter stack is actually 3 separate cabinets and the other uppers’ faces are on a different plane, we have the flexibility needed to make it come out right.

Starting at the right-hand end, we have the mail-sorter stack (just out of frame), silverware & storage cabinet, gap for the dishwasher, main sink base, trash & recycle pullout, and a door stack. They’re all level with one another now, though it took some doing. Under the sink cabinet is a kickspace heater.

We’re lucky that the stove run has no such difficulties, because the pantry cabinet on the end — being one 90-inch-tall monolithic unit — could not be trimmed in height. So we do have 3 inches for the crown moulding (bringing us to 93) on this wall.

Again starting at the right-hand end, we have a general storage cabinet, gap for the stove, two 30″ three-drawer pot & pan cabinets, the base for the prep sink, a cutting board / tray divider pullout, and the aforementioned tall pantry cabinet.

Finally, the installers also built the framework for the peninsula on the fridge run. This is a bit longer than we had originally designed; upon seeing a mockup, the installer and I figured it made sense to extend it to roughly align with the end of the stove run. This gives a much more comfortable seating space for someone to sit and have a drink or chop some vegetables.

We expect the counters to be templated on Monday morning, and the rest of the cabinets to be installed this week. Upper cabinets are a whole lot less work than lowers, so they should go up quickly. But crown moulding and light rail can be time consuming, and they still have to build the rest of the box around the fridge.

We ordered heavy-duty drawer glides on the two pot & pan cabinets, since they’ll bear the most weight. Thus I was concerned when I noticed that those drawer glides are the same as all the others. But a little research showed me that all our drawer glides are the heavy-duty variety (with a 50 kg rating). So either the cabinet company has switched their spec, or someone did us a favor.

The fridge was also delivered this week. We can’t hook it up until its enclosure is built, and its power & water lines are finished. But we can look. I think it’s gonna work out well for us.

I’m realizing I never talked about the pantry shelves. Over Memorial Day weekend, Lis and I went to Container Store and bought hanging rail, shelf standards, and small shelf brackets, plus a set of interlocking plastic drawer bins. I built ten 8″ shelves out of plywood with a moulding applied to the front edge, all painted white, plus an 18″ deep countertop stained with a clear finish. You can see some of the shelves in the second photo in this post. Last weekend I got as far as primer on the shallow shelves, and this weekend I put on the topcoat. I won’t screw them to the shelf brackets until we’re ready to move stuff into the pantry. And I won’t permanently attach the countertop until the carpenters have put baseboard in the pantry, so it’s not in their way. But it’s good to get finish on these shelves now so the paint can fully cure before we try to put anything on them.

On the sunroom front, we did see the footings poured this week. But they needed to cure before supporting weight, and then our main carpenter was moving house, so that’s all that happened this week. I’m a little distressed at the weather forecast for this coming week, since I fear rain will mean additional delay. I’m assured, though, that once it does start it will proceed quickly, since there’s not a lot of coordination between trades required, and they plan to bring in additional personnel to get it done.

Big day

The house was quite a hive of activity today. This is what it looks like to have a concrete truck in your yard, and yet NOT stuck:

Cabinet installation also started today. They decided to start with the lowers, which surprised me a little (it’s easier to get at the walls to install uppers before the lowers are in place), but I’m sure they have their reasons. At the end of the day, the three cabinets beside the pantry are the closest to being in their final locations.

Meanwhile, our garage is less full of cabinets today. Along with all the uppers, most of the drawers are still out here to keep them from getting damaged.

Week 8 report

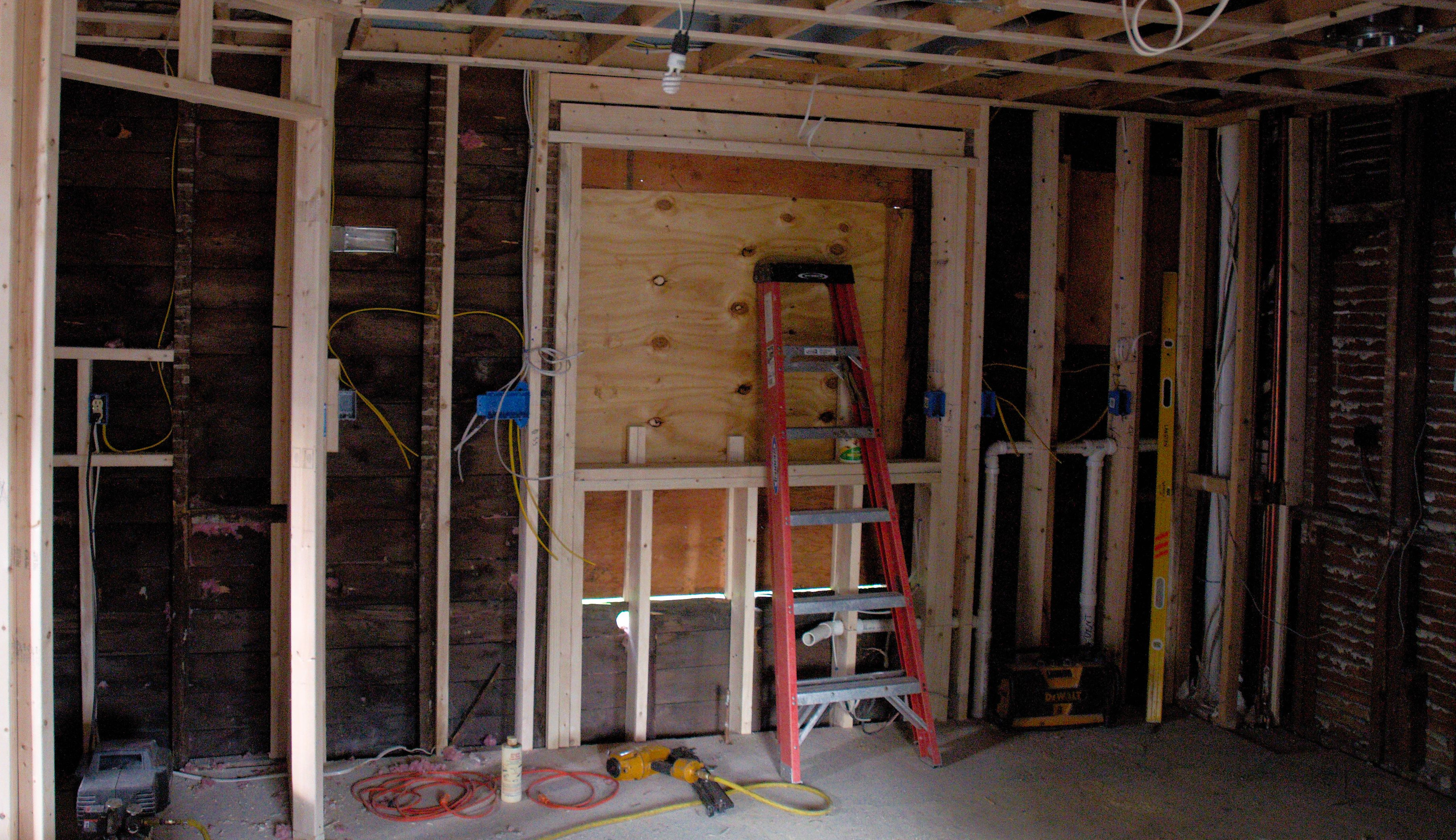

We have a room now! We’re getting close to having something resembling a kitchen.

The oak flooring was installed and had 2 coats of polyurethane applied this week. It looks great! There are a couple spots with some swirly marks visible if you look closely, but overall it looks good, and as Lis says, finally the two halves of the room feel unified. Because the flooring made the room impassable for much of the week, not much else happened inside this week. We did get the replacement backsplash mosaic, and it looks much better. This picture also gives you a good look at the new floor. Any worries we had that the flooring would be too close to the cabinets in color is now officially forgotten.

Another possibility is to put a piece of 1x material on the wall where the white stripe is (same thickness as the baseboards, when they go in), to give it a little three-dimensionality.

On the sunroom portion of the project, our contractor repaired a section of decayed sill. The original (120 year old) beam had decayed away to about half its original size, propped up only because it had a knot in it that did not decay. This knot was holding up the corner of the house! Anyway, it’s all repaired now, ready to accept the ledger for the sunroom. He also dug and put forms in for the footings this week. He had hoped to get them poured this week too, but the rainy weather delayed the excavation for just long enough to prevent that from happening.

It amazes me that these footings — for a permanent, enclosed structure — are just 12″ in diameter (with a “bigfoot” flared base), in contrast to the footings required for our friends’ new deck that I’ve been helping with, which are required to be 18″. And Greg, you will be jealous to hear that the excavation found no rocks bigger than about grapefruit size.

This coming week promises to be an exciting one. Tomorrow, Lis and I are going to Container Store to buy some parts needed to build the shelves inside the pantry, which I hope to get a start on Monday. And Tuesday, we will have quite a crowd at the house as our cabinets start to be installed — complete with plumber and electrician to hook up the kickspace heaters — plus the pouring of the footings.

Floor

Wow, in one day they installed, sanded, and put the first coat of finish on the kitchen floor. Pics to follow once we’re allowed back in there!

Week 7 report

Major excitement this week!

First event… we passed framing inspection, clearing the way for blueboard on Wednesday and skim-coat plaster on Thursday. The weather has been so nice for the past few days that the plaster dried out nicely, and we were able to paint today. I started around 9 this morning with primer. Lis left work early to come home around 3:30. We finished up around 7:30 pm. You can see the results in the time-lapse gallery but I’ll post it here as well.

Second event… we have the permit for the sunroom portion of the project. We expect at least some progress toward new footings this coming week, with major framing to commence the week of Memorial Day.

Third event… the cabinets were delivered this morning. They’re camping out in our garage this coming week while the flooring goes in, and are expected to be installed the week of Memorial Day. Here they all are, taking up our entire garage.

And here’s the custom mail sorter we had made. The shelves on the right-hand side are adjustable, stacked together as you see here for shipping; in the final configuration we anticipate having 6 slots on the right.

See my Project 365 entry for today for another representative cabinet.